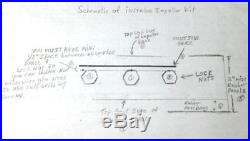

In an effort to serve you better, we have added many new products. Using both 1/4″ & 3/8″ thick rubber paddles. Search for “Snow Blower Impeller Kit” to see our other listings and BEWARE of Imitations! Got an older two-stage snow blower that isn’t throwing snow like it used to? Frustrated with your discharge chute clogging up every time the snow gets wet or too heavy? If your TWO-STAGE snow blowers discharge chute keeps clogging up when you try to move very heavy or wet snow or slush, it is probably because of a large gap or space between the impeller blades (the 2nd set of vertical blades behind the main front horizontal auger blades) and the cylindrical chamber in which it rotates. This “gap” allows snow and slush to slip by the blades and build up around the impeller and in the discharge chute clogging it. This gap also decreases the efficiency of the impeller’s ability to propel the snow up the chute resulting in less throwing distance. This problem is well known to people with two-stage snow blowers, and the easy and the quick, inexpensive fix is to modify the impeller blades by adding a strip of reinforced rubber to each one of them to eliminate this gap. It is HIGHLY recommended that you install a Snow Blower Impeller Kit on each blade however, because only modifying some but not all of the blades will cause a harmonic imbalance in the spinning impeller which could easily cause excessive wear on the impeller shaft bearing resulting in very costly repairs! If you have a single-stage snow blower, or your gap is less than 1/4″ or greater than 5/8″, you probably don’t need or can’t use this fix. Install this Snow Blower Impeller Kit onto your two-stage snow blower and never fear another snow fall again! Virtually eliminate the clogged chute syndrome when moving wet or heavy snow! Dramatically increase the snow throwing distance of your snow blower! Depending on how handy you are, this kit can be installed in 1-2 hours without too much difficulty! Each Snow Blower Impeller Kit contains the following Top Quality, “Made in the USA” materials. (1) 3/8″ thick rubber paddle (2″W x 5L) – (trim to fit as needed – See FAQs below). Made from Styrene Butadiene rubber (SBR rubber). SBR rubber with minimum tensile strength of 725 PSI (5 MPA). Hard rubber with a durometer of 65-75. (1) metal strap with holes – 1 3/8″ W x 3 3/4″L. Punched flat bar grade 5 steel, 1/16 thick. (3) bolts 5/16-18 x 1 in. Coarse thread w/ 5/16-18 lock nuts (use 1/2 wrench & socket). Hex bolts, grade 5 steel. Hex lock nut s nylon insert, grade 5 steel steel. (1) self-tapping screw (#14 x 1) (not shown in picture to right) Why? S heet metal screw, Hex washer head self drilling, grade 5 steel. Custom sized metal straps and rubber paddles are available upon request at no extra charge!! Ask me about it before ordering! 4 Blade Kit Contents: For Three and Four Blade Snow Blower Impellers. Qty (4) rubber paddles. Qty (4) metal straps. Qty (12) bolts & lock nuts. Qty (4) self-tapping screws. Installation Instructions & FAQs. If using with a three-blade machine, keep extra Kit as spare. This not only virtually. The problem of wet snow clogging up the chute, but may. The throwing distance of your snow blower by up to 30-50% or more! I say “virtually” because you can never completely eliminate clogging when the moisture content of the snow is well over. 0% (eg; very wet slush turns to ice in your chute), but for every 10 times you previously had to clean out your chute, you “might” only need to do it once with this kit installed and you will see a noticeable increase in throwing distance regardless! Get this kit and turn your snow blower into the snow-moving beast it was meant to be! To see real-life examples of this modification and the effect on a snow blower’s performance, go to Youtube. Com, search for. Snow Blower Impeller Kit. Or some variation on that theme and watch the videos, or you can watch this excellent video by Ari P. Describing the modification and its effect on your snow blower. Watch the video —-> Ari P. S Impeller Modification Description. Single, Three, Five and Six Blade Kits are also available. See my other listings! Export Label # only. If you are dissatisfied in any way, or need assistance with this item, please let me know and I will try my best to resolve the issue to your complete satisfaction! Remember , we offer a Lifetime Moneyback Guarantee! If you are ever dissatisfied with this product. Q- What is the purpose of the Snow Blower Impeller Kit? This kit reduces the existing gap between the snow blower’s impeller blades and the impeller chamber wall. The smaller the gap, the greater your machine’s operational efficiency and snow throwing capability will be, and the less likely that your machine will clog up with snow. Q- Why would I want to install this? If the existing gap on your machine is between 1/4 & 5/8 or greater, then your machine is losing a significant amount of efficiency and power in throwing snow. This loss in efficiency results in more clogging in your discharge chute, and less throwing distance. As with any impeller device snow blower, water pump, etc. , simple physics proves that maximum efficiency is achieved when there is no gap between the impeller’s blades and the impeller chamber’s walls. For any excellent explanation on this subject, watch. Thanks for allowing me to share this Ari! Q- How do I know if I need to install this kit? A- If you have a large gap between your impeller blades and the impeller chamber wall, your machine clogs up with snow frequently and it doesn’t throw snow very far any more, then this kit might be for you. Some newer, more powerful snow blowers might have a significant gap but still work fine, so the bottom line is this… Are you happy with your snow blower’s performance? Q- Why don’t the manufacturers eliminate this gap from their machines? A- The reason is that on machines with straight shaft mounted impellers (which most are) the impellers bearing wears over time and this wear causes some degree of wobble in the impellers rotation. If the metal impeller blade was made to fit “flush” against the metal cylinder walls with no gap, there would be no tolerance for “rotational wobble”. They leave this gap to accommodate this wobble if/when it happens and avoid a situation where you have metal scraping on metal. That could cause significant damage to the impeller and the cylinder walls in which it rotates requiring very expensive repairs. Since this modification uses rubber paddles which wear down evenly as they come in contact with the cylinder walls, any possible future wobble in the impellers rotation is negated without compromising the snow blowers operational integrity or efficiency at moving snow and slush. Q- If I install your Snow Blower Impeller Kit , will it eliminate all clogging? Theoretically, yes, but the reality is that it depends on a number of things. Snow conditions, engine displacement, torque output, etc. For example, snow that has a water consistency of 40% or more (slush) can turn into ice in your snow blower’s discharge chute and clog the chute regardless of your machine’s output capability. This kit reduces the likelihood of that happening but. Can prevent that completely. Q- Does engine size really matter? In most cases, Yes, however don’t confuse engine size (whether rated in HP or CCs) with the ability to move snow efficiently. Sure, a 10HP or 305CC engine has more potential power than a 5HP or 271 CC engine, but the power output and ability to move snow is much more dependent on impeller revolutions and torque than just engine size. The faster your impeller spins and the larger your machine’s foot pounds of torque performance specification is, the greater its’ ability to power through snow of any consistency. Where the engine size is most important is in it’s ability to handle an increasing load without stalling. It is a misconception that all 10HP or 305CC machines are the same, because they might have different torque ratings or revolutions per minute. Here’s an approximate conversion chart courtesy of. 123 cc = 4 hp 179 cc = 5 hp 208 cc = 8 to 9 Gross Torque = 5.5 to 6 hp 277 cc = 11 to 11.5 Gross Torque = 7 to 8 hp. 305 cc = 13.5 to 14.5 Gross Torque = 9 to 10 hp 342 cc = 15.5 to 16.5 Gross Torque = 11 to 12 hp 357 cc = 14 hp 420 cc = 15 hp. Q- What exactly is a Snow Blower Impeller Kit? This kit contains all of the materials necessary to modify. Snow blower impeller blade. Q- Where are the materials in the kit made? A- Each Snow Blower Impeller Kit contains Top Quality, ” Made in the USA ” materials. Q- Why would I ever order a single-blade kit? You might want a spare kit, or maybe you previously ordered a Three-Blade kit and later realized you really needed a Four-Blade kit. No, we offer a. Three, Four and Five Blade kit in both 1/4″ thick and 3/8″ thick rubber paddle configurations. Each of these contains all of the materials necessary to modify that number of impeller blades in your machine. For example, if your two-stage snowblower has three impeller blades, you can order either the Three-Blade kit, or the Four Blade kit and keep the extra set as a spare. Q- Why do you offer kits with rubber paddles in both 1/4″ and 3/8″ thick configurations? A- There are many different configurations of snow blowers in operation, and many different conditions under which they operate. We offer these two configurations so you can choose which kit best fits your particular needs. Q- Can I install this kit on a two-stage snow blower with plastic impeller blades? I’m sorry but I just do not know if it would work, or if your plastic impeller blades would crack during installation or break during use because the drilled bolt holes have weakened the blades too much to handle the stress. Of course, I do not know that the kit wouldn’t work as advertised either but quite honestly, I don’t think the plastic impeller blades would be strong enough or worth the risk. My recommendation is NO but it’s your call! If the impeller blades did crack or break, you’d have to replace the entire impeller unit! Q- How do I know whether your standard Snow Blower Impeller Kit will fit my impeller blades? Each kit contains 1 3/8W x 3 3/4L metal straps and 2W x 5L rubber paddles. To determine if the standard kit will fit. Measure the flat part of the TOP surface of your impeller blade, before it curls up. That determines the length of the metal strap and rubber paddle you will need. You can install these so that they wrap up on the curl as well, but we’ve found that the benefit is not worth the increase in difficulty you will have in modifying the kit to fit, and then installing it. Most of the work done in moving snow is done by the flat part of the impeller blade. Q- If necessary, how do I modify the metal straps and/or rubber paddles to fit? You can cut the metal straps with a hacksaw and you can easily trim the rubber paddles to fit with a sharp utility knife. Q: If I can’t, or don’t want to do it myself, can you customize my kit for me? Just measure the impeller blades as described previously and let us know what you want before you order. Q- Should the rubber paddles in your Snow Blower Impeller Kit be mounted so they are pressing tightl y against the impeller chamber wall? They should be installed so they are barely touching the impeller chamber wall. Remember, ANY decrease in the gap between the impeller blades and the chamber wall will result in a significant improvement in operational efficiency and throwing distance! Q- Should I be concerned about the metal brace on the underside of the impeller blade? In some instances, the position of the metal brace might interfere with the bolt holes and installation of the bolts w/lock-nuts used to secure the kit to the impeller blade. You need to make sure that there is room to screw on the lock nuts on the underside of the impeller blade, otherwise, you might be able to use a self-tapping screw included in the kit. You need to have a minimum of 1/8 space between the underside brace and the lock nut in order to tighten the lock nut with a wrench. If you don’t, you will need to use a self-tapping screw in. Q- What about obstructions in the impeller chamber walls? A- On some machines, there are round-headed carriage bolts that protrude into the impeller chamber wall. These bolt heads might interfere with the rubber paddles as they rotate by causing damage to the paddles. It is very important to inspect your impeller chamber walls to see if this situation exists! If it does, you can still install the kit but you have to leave a gap large enough so that the paddles will not come into contact with the protruding bolt heads. Remember, the idea of this kit is ideally to eliminate the gap, however ANY reduction of the gap WILL improve the efficiency and snow throwing capability of your machine! Q- What else should I consider when fitting my rubber paddles to my impeller blades? A- You want to eliminate the existing gap as much as possible in all respects, so when you trim the rubber paddles for final fit, try to match the curvature of the impeller chamber walls’ sides and top as much as possible. NOTE: if the gap varies around the chamber wall, you MUST install the rubber to fit the spot where the gap is the smallest, otherwise, the rubber will fail!! Also , don’t install the rubber paddles with more than 5/8 of rubber overhanging the leading edge of the impeller blade because that seems to be the stress point for these paddles and they might break off under heavy load conditions eg; heavy snow, slush, etc. Why are self-tapping screws included? And foremost, drilling a hole through the metal impeller blades can be very difficult, so the included instruction sheet explains that you can use them to make a pilot hole where the bolt will go first, then drill out the pilot hole for the bolt which is so much easier. You certainly don’t have to do this but I’ve found it makes the job easier. In those instances where the brace on the underside of the impeller blade is in the way of where you would drill a bolt hole, a self-tapper screwed down next to, but not in to, the underside brace works well as an emergency substitute to the bolt & nut. For that one location. The instruction sheet explains the risk/benefit scenario between self-tappers and bolts and specifically counsels this as an emergency measure, and the use of bolts in the other hole(s). Securing the kit to the impeller blade to insure the integrity and strength of the attachment. Hence, there are self-tappers included to meet either scenario. If you don’t need them, don’t use them! Q- Why do you use zinc-coated steel instead of stainless steel components? A- The metal components included in these kits are zinc plated grade 5 steel which is used because, while slightly less corrosion resistant than stainless steel, zinc plated grade 5 steel is harder and more durable, and is the most common bolt found in automotive applications. Stainless steel is an alloy of low carbon steel and chromium. It is a common misconception that stainless steel is stronger than regular steel. In fact, due to the low carbon content, stainless steel cannot be hardened. Therefore when compared with regular steel it is slightly stronger than an un-hardened (grade 2) steel fastener but significantly weaker than hardened (grades 5 & 8 and alloy steel) steel fasteners. Stainless steel is more corrosion resistant than zinc-plated steel because the anti-corrosive properties are inherent to the metal, it will not lose this resistance if scratched during installation or use, while zinc-plated and galvanized steel are, to some degree, more susceptible to corrosion over time when the surface coating is scratched. In this application, it was decided that the difference in corrosion resistance was negligible over the typical useful life of a snow blower, and that the hardness and overall durability of zinc plated grade 5 steel was a superior choice for the hardware used in this kit. Q- What is your Lifetime Moneyback Guarantee! Q- What if I damaged a rubber paddle(s) and need a replacement rubber paddle(s), not a whole kit? Please include any pictures of the damage and provide us as much detail as to the circumstances surrounding the event as you can. Eg; snow/weather conditions, etc. If we determine that the cause of the damage. Due to a defect in the rubber, we will replace the damaged rubber paddles at no cost to you. If we determine that the cause of the damage. Due to a defect in the rubber. (3/8 thick) + SH. You will need to provide us with the. That accompanied your order as. An excellent website full of unbiased advice, information and reviews of many old and current snow blowers can be found at. A- We are the industry leader and stand behind our products 100% with a Lifetime Moneyback Guarantee! Simply put, “We are not satisfied until you are satisfied”! USPTO SnowThrower Impeller Kit Reg. USPTO Snow Blower Impeller Kit Reg. The item “SNOW BLOWER IMPELLER KIT 3/8 HD 4-Blade Universal Modifies 2-Stage Machine” is in sale since Wednesday, January 20, 2016. This item is in the category “Home & Garden\Yard, Garden & Outdoor Living\Outdoor Power Equipment\Snow Blowers”. The seller is “naneki.r” and is located in Pelham, New Hampshire. This item can be shipped to North, South, or Latin America, all countries in Europe.

- Type: Two Stage

- Power Source: Gas

- Clearing Width: All

- Model: SBIK-4H

- MPN: SBIK384

- Country of Manufacture: United States

- Brand: SBIK

- Country/Region of Manufacture: United States

This article was filed under snow.